Introduction to SPI Interface

Serial peripheral interface (SPI) is one of the most widely used interfaces between microcontroller and peripheral ICs such as sensors, ADCs, DACs, shift registers, SRAM, and others. This article provides a brief description of the SPI interface followed by an introduction to Analog Devices’ SPI enabled switches and muxes, and how they help reduce the number of digital GPIOs in system board design.

SPI is a synchronous, full duplex main-subnode-based interface. The data from the main or the subnode is synchronized on the rising or falling clock edge. Both main and subnode can transmit data at the same time. The SPI interface can be either 3-wire or 4-wire. This article focuses on the popular 4-wire SPI interface.

Interface

Figure 1. SPI configuration with main and a subnode.

4-wire SPI devices have four signals:

- Clock (SPI CLK, SCLK)

- Chip select (CS)

- main out, subnode in (MOSI)

- main in, subnode out (MISO)

The device that generates the clock signal is called the main. Data transmitted between the main and the subnode is synchronized to the clock generated by the main. SPI devices support much higher clock frequencies compared to I2C interfaces. Users should consult the product data sheet for the clock frequency specification of the SPI interface.

SPI interfaces can have only one main and can have one or multiple subnodes. Figure 1 shows the SPI connection between the main and the subnode.

The chip select signal from the main is used to select the subnode. This is normally an active low signal and is pulled high to disconnect the subnode from the SPI bus. When multiple subnodes are used, an individual chip select signal for each subnode is required from the main. In this article, the chip select signal is always an active low signal.

MOSI and MISO are the data lines. MOSI transmits data from the main to the subnode and MISO transmits data from the subnode to the main.

Data Transmission

To begin SPI communication, the main must send the clock signal and select the subnode by enabling the CS signal. Usually chip select is an active low signal; hence, the main must send a logic 0 on this signal to select the subnode. SPI is a full-duplex interface; both main and subnode can send data at the same time via the MOSI and MISO lines respectively. During SPI communication, the data is simultaneously transmitted (shifted out serially onto the MOSI/SDO bus) and received (the data on the bus (MISO/SDI) is sampled or read in). The serial clock edge synchronizes the shifting and sampling of the data. The SPI interface provides the user with flexibility to select the rising or falling edge of the clock to sample and/or shift the data. Please refer to the device data sheet to determine the number of data bits transmitted using the SPI interface.

Clock Polarity and Clock Phase

In SPI, the main can select the clock polarity and clock phase. The CPOL bit sets the polarity of the clock signal during the idle state. The idle state is defined as the period when CS is high and transitioning to low at the start of the transmission and when CS is low and transitioning to high at the end of the transmission. The CPHA bit selects the clock phase. Depending on the CPHA bit, the rising or falling clock edge is used to sample and/or shift the data. The main must select the clock polarity and clock phase, as per the requirement of the subnode. Depending on the CPOL and CPHA bit selection, four SPI modes are available. Table 1 shows the four SPI modes.

| Table 1. SPI Modes with CPOL and CPHA | ||||

| SPI Mode | CPOL | CPHA | Clock Polarity in Idle State | Clock Phase Used to Sample and/or Shift the Data |

| 0 | 0 | 0 | Logic low | Data sampled on rising edge and shifted out on the falling edge |

| 1 | 0 | 1 | Logic low | Data sampled on the falling edge and shifted out on the rising edge |

| 2 | 1 | 0 | Logic high | Data sampled on the rising edge and shifted out on the falling edge |

| 3 | 1 | 1 | Logic high | Data sampled on the falling edge and shifted out on the rising edge |

In these examples, the data is shown on the MOSI and MISO line. The start and end of transmission is indicated by the dotted green line, the sampling edge is indicated in orange, and the shifting edge is indicated in blue. Please note these figures are for illustration purpose only. For successful SPI communications, users must refer to the product data sheet and ensure that the timing specifications for the part are met.

Figure 2. SPI Mode 0, CPOL = 0, CPHA = 0: CLK idle state = low, data sampled on rising edge and shifted on falling edge.

Figure 3 shows the timing diagram for SPI Mode 1. In this mode, clock polarity is 0, which indicates that the idle state of the clock signal is low. The clock phase in this mode is 1, which indicates that the data is sampled on the falling edge (shown by the orange dotted line) and the data is shifted on the rising edge (shown by the dotted blue line) of the clock signal.

Figure 3. SPI Mode 1, CPOL = 0, CPHA = 1: CLK idle state = low, data sampled on the falling edge and shifted on the rising edge.

Figure 4 shows the timing diagram for SPI Mode 3. In this mode, the clock polarity is 1, which indicates that the idle state of the clock signal is high. The clock phase in this mode is 1, which indicates that the data is sampled on the falling edge (shown by the orange dotted line) and the data is shifted on the rising edge (shown by the dotted blue line) of the clock signal.

Figure 4. SPI Mode 3, CPOL = 1, CPHA = 1: CLK idle state = high, data sampled on the falling edge and shifted on the rising edge.

Figure 5 shows the timing diagram for SPI Mode 2. In this mode, the clock polarity is 1, which indicates that the idle state of the clock signal is high. The clock phase in this mode is 0, which indicates that the data is sampled on the rising edge (shown by the orange dotted line) and the data is shifted on the falling edge (shown by the dotted blue line) of the clock signal.

Figure 5. SPI Mode 2, CPOL = 1, CPHA = 0: CLK idle state = high, data sampled on the rising edge and shifted on the falling edge.

Multi-Subnode Configuration

Multiple subnodes can be used with a single SPI main. The subnodes can be connected in regular mode or daisy-chain mode.

Regular SPI Mode:

Figure 6. Multi-subnode SPI configuration.

In regular mode, an individual chip select for each subnode is required from the main. Once the chip select signal is enabled (pulled low) by the main, the clock and data on the MOSI/MISO lines are available for the selected subnode. If multiple chip select signals are enabled, the data on the MISO line is corrupted, as there is no way for the main to identify which subnode is transmitting the data.

As can be seen from Figure 6, as the number of subnodes increases, the number of chip select lines from the main increases. This can quickly add to the number of inputs and outputs needed from the main and limit the number of subnodes that can be used. There are different techniques that can be used to increase the number of subnodes in regular mode; for example, using a mux to generate a chip select signal.

Daisy-Chain Method:

Figure 7. Multi-subnode SPI daisy-chain configuration.

In daisy-chain mode, the subnodes are configured such that the chip select signal for all subnodes is tied together and data propagates from one subnode to the next. In this configuration, all subnodes receive the same SPI clock at the same time. The data from the main is directly connected to the first subnode and that subnode provides data to the next subnode and so on.

In this method, as data is propagated from one subnode to the next, the number of clock cycles required to transmit data is proportional to the subnode position in the daisy chain. For example, in Figure 7, in an 8-bit system, 24 clock pulses are required for the data to be available on the 3rd subnode, compared to only eight clock pulses in regular SPI mode. Figure 8 shows the clock cycles and data propagating through the daisy chain. Daisy-chain mode is not necessarily supported by all SPI devices. Please refer to the product data sheet to confirm if daisy chain is available.

Figure 8. Daisy-chain configuration: data propagation.

Analog Devices SPI Enabled Switches and Muxes

The newest generation of ADI SPI enabled switches offer significant space saving without compromise to the precision switch performance. This section of the article discusses a case study of how SPI enabled switches or muxes can significantly simplify the system-level design and reduce the number of GPIOs required.

The ADG1412 is a quad, single-pole, single-throw (SPST) switch, which requires four GPIOs connected to the control input of each switch. Figure 9 shows the connection between the microcontroller and one ADG1412.

Figure 9. Microcontroller GPIO as control signals for the switch.

As the number of switches on the board increases, the number of required GPIOs increases significantly. For example, when designing a test instrumentation system and a large number of switches are used to increase the number of channels in the system. In a 4 × 4 cross-point matrix configuration, four ADG1412s are used. This system would require 16 GPIOs, limiting the available GPIOs in a standard microcontroller. Figure 10 shows the connection of four ADG1412s using the 16 GPIOs of the microcontroller.

Figure 10. In a multi-subnode configuration, the number of GPIOs needed increases tremendously.

One approach to reduce the number of GPIOs is to use a serial-to-parallel converter, as shown in Figure 11. This device outputs parallel signals that can be connected to the switch control inputs and the device can be configured by serial interface SPI. The drawback of this method is an increase in the bill of material by introducing an additional component.

Figure 11. Multi-subnode switches using a serial-to-parallel converter.

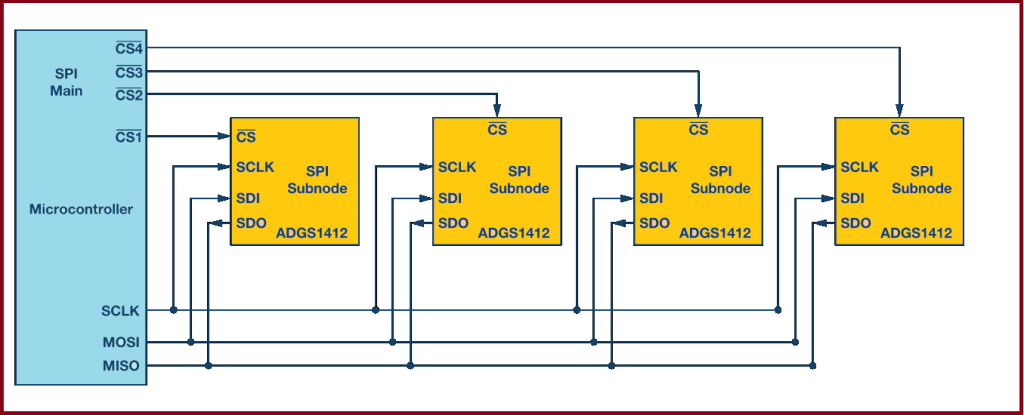

An alternative method is to use SPI controlled switches. This method provides the benefit of reducing the number of GPIOs required and also eliminates the overhead of additional serial-to-parallel converter. As shown in Figure 12, instead of 16 microcontroller GPIOS, only seven microcontroller GPIOs are needed to provide the SPI signals to the four ADGS1412s.

Figure 12. SPI enabled switches save up microcontroller GPIOs.

The switches can be configured in daisy-chain configuration to further optimize the GPIO count. In daisy-chain configuration, irrespective of the number of switches used in the system, only four GPIOs are used from the main (microcontroller).

Figure 13. SPI enabled switches configured in a daisy chain to further optimize the GPIOs.

Difference between UART, I2c, and SPI

| Protocol | Complexity | Speed | # of Devices | # of Wries | Duplex | No. of master and slave | |

| UART | Simple | Slowest | Up to 2 devices | 1 | Full Duplex | Single to Single | |

| I2C | Easy to chain multiple devices | Faster than UART | Up to 127, but gets complex | 2 | Half Duplex | Multiple slaves and master | |

| SPI | Complex as device increases | Fastest | Many, but gets complex | 4 | Full Duplex | 1 master, multiple slaves |

Advantages of using SPI

- Support full-duplex communication, which means data can be transmitted and received at the same time.

- Better signal integrity, supporting high-speed applications.

- The hardware connection is simple, only four signal lines are needed (some applications can be reduced to three).

- No transceiver required.

- The slave device does not need to address.

Disadvantages of using SPI

- Short transmission distance.

- There is no flow control specified, and no acknowledgement mechanism confirms whether data is received, unlike I2C.

- More Pin ports are occupied, the practical limit to the number of devices.

- No form of error check unlike in UART (using parity bit).

- Interrupt operation can only be done through additional signal lines.

- Only 1 master.

Leave a comment